Propellers : The Sails You Don't See

As more and more sailors make the transition from sailboats to power the importance of understanding basic propeller theory is important. Like your sails, the propeller's performance is directly linked to its size and shape and this article was designed to touch on the importance of boat propeller tuning from a sailor's perspective.

Moving a boat weighing tons through the water at planing speeds takes lots of energy and the blades of the propeller are what translate the engines horsepower into thrust. Thus, blade loading on a propeller is measured in thousands of PSI. It takes a defined amount of energy to move a particular hull at hull speed and that energy is either dispersed by the sails and or the propeller. The comparatively massive area of the sails disperses the load almost evenly thus the sail loading is measure in hundreds of PSI rather than thousands. When you think of the load on a mainsheet in 25kts of breeze it gives you some appreciation of the amount of energy that must be transferred to the propeller to make a powerboat hull climb out of the water and plane.

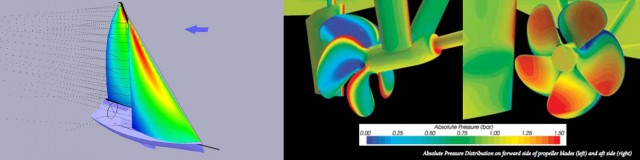

The driving force of sailboats are the sails. How they react with the wind dictates how fast the boat will be propelled through the water and if you are a sailor then you know how important sail trim can be. In a good breeze a properly trimmed sail will push the performance limits of the hull and make 6 knots feel like 60, sort of. To take the experience even further, a new sail with a modern cut built with space age materials makes the experience even better by allowing the boat to achieve maximum performance quickly. A sails shape causes a pressure differential and this pressure differential is what causes the boat to move. This same phenomenon happens when a propeller is rotated through the water and many of the same principals apply. Uniformity of shape is perhaps the most significant aspect of propeller design and it is also one of the most import to maintain.

A boat propeller is a screw that threads into water. The distance a screw travels during a single revolution is what is referred to as pitch and it is assigned a number in inches. The propeller's diameter is simply the diameter of the propeller from blade tip to tip and is also described in inches. So a 25x21 propeller is 25" in diameter and will travel 21" per revolution assuming a theoretical propeller efficiency of 100%. Like a sail, the shape of the propeller plays a large role in how it performs and there are different materials used per the design application. A high-tech sail uses very low stretch materials to maintain its shape in the desired wind range for the sail. Boat propellers are made from metals that are strong, stiff and corrosion resistant so that they maintain their shape while rotating at thousands of RPM at very high speeds comparatively. A good sailor always has an eye on the trim to ensure the boat is performing it's best and poorly trimmed sails not only cause poor performance but also cause unnecessary wear and fatigue on the rigging. This also holds true with a powerboat's propeller with the biggest difference being that a sailor has an eye on the sails the entire time they are underway.

Making sure your boat propeller is balanced and properly sized is just as important as keeping the sails trimmed on a sailboat and many, most, power boaters don't. Given that the propeller is the boats only interface with the water with regards to propulsion the importance of a properly tuned "wheel" cannot be over stressed.

Tuning a propeller is a fairly inexpensive endeavor and if you haven't had a prop scan in recent memory it should be done. Good boat prop shops will use laser scanning and sophisticated programs like Hale MRI and Propscan to evaluate and possibly alter the shape of your propeller to ensure optimum shape much like the way a sailmaker uses computer design to build shape into a sail.

In order for a prop shop to advise you on a propeller shape and design you must have performance data obtained from sea trialing your own boat. Run the boat from headway speed through wide open throttle and note the speed achieved at 200 RPM increments. Do this several times upwind, downwind, and in as many different conditions as possible - loaded unloaded etc. Pay special attention to 80% of max RPM or your optimized cruising RPM and max RPM. These are the two most significant data points when tuning a wheel and without them a prop shop will be shooting in the dark. Prop diameter is also an important factor when checking a propeller design for optimum performance. The larger the propeller the more efficient it will be. Measure from the center of the propeller shaft to the closest part of the hull or skeg. The rule of thumb for tip clearance is 17% of the diameter of the propeller. For example, a 25" propeller should have a minimum of 4.25" of clearance between the blade tip and the hull. Walk around any boat yard in the winter and you will see lots of boats with improperly sized propellers.

The properly sized and pitched propeller will do wonders for the performance of the boat and having the right prop size will decrease fuel burn, prolong an engine's life, run quieter and may even increase the boats speed. Just as a properly trimmed sail makes all the difference, the right propeller will take your power boating to the next level.

Stay Informed

When you subscribe to the blog, we will send you an e-mail when there are new updates on the site so you wouldn't miss them.

Comments